Production is the main and core competence of e-liquids and raw materials manufacturing companies. At the same time, it is not the only factor that determines the final quality of the nicotine products. Let’s take a closer look at the three other factors that should be properly managed to make the end customer satisfied: packaging, transport, and storing.

See also:

- OEM Services And Private & White Label: 9 Reasons To Choose Chemnovatic As The Best Business Partner

- How To Start And Grow E-Liquid Brand?

- E-Liquid Manufacturing Standards: Tips For Producers And Brand Owners

- E-Liquid Manufacturers: Best Practices

- Pharmaceutical Quality Of E-Liquids: What You Should Know?

- Storing And Handling Pure Nicotine And Nicotine Salts

- Safe Usage Of Chemicals [Guide]

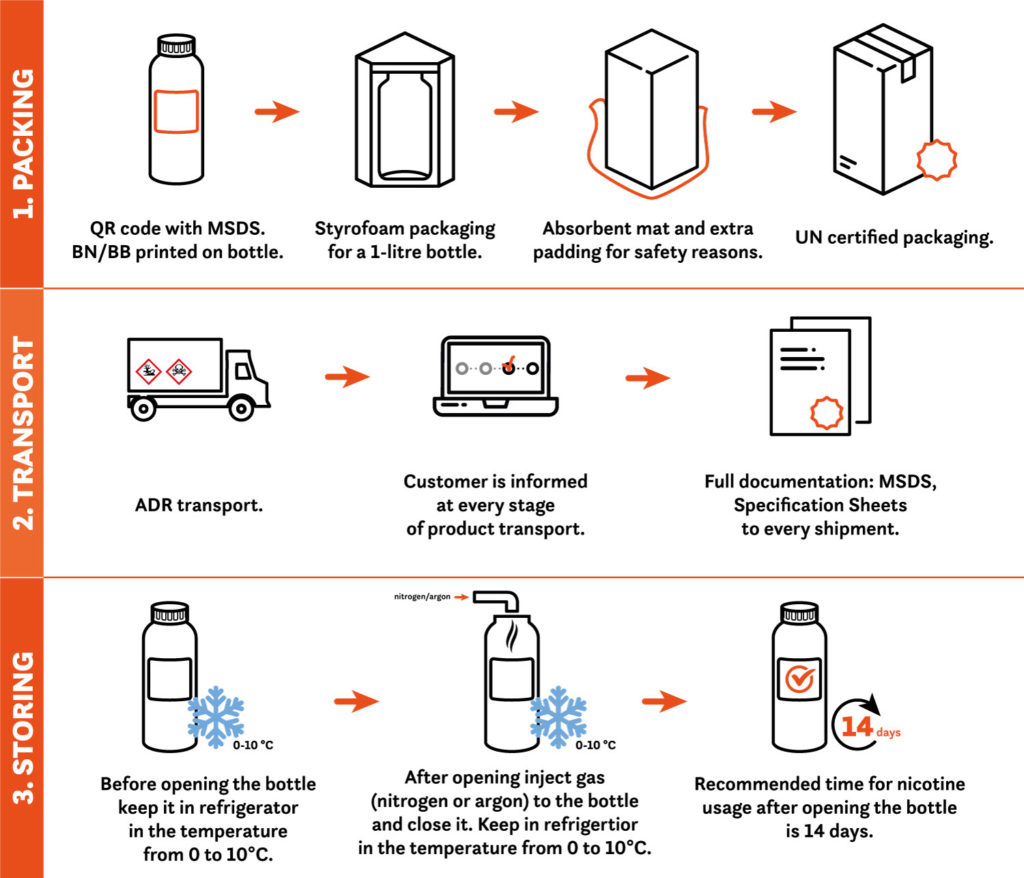

1. Nicotine products: Packaging

The choice of packaging depends on the type of product, the recommended storage temperature or sensitivity to light. In case of raw materials for e-liquid production, some of them, like pure nicotine, nicotine salts or highly concentrated nicotine bases demand special packaging, as they pose a threat to people and nature.

One of the main ways to protect the environment from danger is the use of properly tested and certified packaging. These packagings are subject to many tests, including tightness, pressure and crushing. All this in order to effectively contain dangerous substances inside the packaging, even in adverse conditions, i.e. during an accident.

Learn more:

Why does the proper packaging matter?

- It prevents the product from losing its properties.

- It serves to keep its standard value as long as possible (for the safety of the end customer).

- It ensures that the product’s appearance and original packaging remains aesthetic.

- It ensures safety in case of an accident.

- It makes the traces of potential damage easy to notice to protect consumers from using defective e-cigarette products.

- It protects the environment from danger.

Check more:

Chemnovatic original pure nicotine packaging always consists of:

- Chemnovatic security seal.

- PureNic 99+ label contains all required information, QR code for the Safety Data Sheet and warning symbols. The batch number and best before date are printed on the bottle.

- Styrofoam packaging for a 1-litre bottle.

- To prevent leakage styrofoam packaging is additionally packed into a plastic bag and secured with Chemnovatic tape.

- Absorbent mat and extra padding for safety reasons. All Chemnovatic PureNic 99+ nicotine shipments contain Certificate of Analysis inside and Safety Data Sheet on the outside.

- UN certified packaging.

- The outside of the collective box is covered with UN markings “dangerous to the environment” and a “toxic product” in accordance with the given nicotine class and the ADR convention or IATA regulation.

2. Nicotine Products: Transport

Customers ordering pure nicotine, nicotine salts, or other sensitive and hazardous substances often ask about the possibility of shipping products with the use of regular shipping methods. Unfortunately, from the legal point of view and for security reasons it is not allowed. Dangerous products require ADR (road), IATA (air), or IMDG (sea) transport.

Transport of hazardous materials – basic requirements

The ADR/IATA/IMDG Conventions are international, very detailed regulations used in the transport of dangerous goods, which describes the risks posed by the transport of dangerous goods and how to prevent these risks. The above conventions enable quick and precise determination of transport requirements and contribute to a uniform interpretation of the rules in the field of transport of dangerous goods.

All hazardous materials are divided into 13 hazard classes. Each load must be given a special four-digit UN number that identifies the hazardous properties of the product.

The ADR/IATA/IMDG Conventions also specifies the detailed conditions for the packing/labelling of dangerous goods, and vehicles marking (goods are required to be marked with warning stickers). ADR/IATA/IMDG Conventions determines provisions regarding vehicles and transport as well as requirements for the vehicle crew and all participating persons.

The addressees of the ADR/IATA/IMDG provisions are all participants of the transport, i.e. carriers, producers of hazardous materials and their consignors, designers of packaging and tanks, technical supervision (research and approval units), vehicle manufacturers and recipients of hazardous materials.

Quantitative restrictions on the transport of nicotine and other dangerous goods

ADR (road) transport is a point-system transport, one vehicle cannot carry more goods whose total points exceed the number specified in the regulations, e.g. 1L of pure nicotine has 3 points and 1 car can transport up to 1000 points, therefore it limits the maximum quantity to 333L of pure nicotine within one vehicle provided that the vehicle is not loaded with other hazardous products, which might decrease the total points capacity of a given vehicle.

This is the reason why ADR road shipments take some longer time than regular courier companies shipments – they simply need to wait in reloading storages for an available vehicle which can be loaded with a certain amount of points.

All low-concentration nicotine products (containing less than 36mg/ml of pure nicotine) fit into the category of standard, non-hazardous products and can be transported with the ordinary courier company. These products are not subject to the ADR/IATA/IMDG Conventions.

Dangerous substances transport is more time-consuming

Another important factor for which dangerous materials transport may take a little more time is the fact that it undergoes a number of documentation controls at reloading points which may also prolong the transportation time. All this results in longer and more expensive delivery than regular goods, which may be surprising for the recipients not used to ordering high-concentration nicotine products.

Depending on the country of destination due to documents checks, dangerous substances transport takes more time than courier transport of non-dangerous products. At the same time, as in any business, the time of delivery is an important factor and at Chemnovatic we take great care to speed up the process and all the actions that are in our control.

Cost of shipping

The cost of shipping a given product depends on the weight of the total products ordered (the larger the order, the higher total shipping cost, but the lower cost per litre, assuming that the order effectively fits the vehicle shipping capacity).

The total cost of shipping includes the cost of insurance for some of the shipments (not always insurance is possible – it depends on the chosen transport company), the cost of certified packaging, tolls and the distance from the place of shipment to the destination and, of course, if products require ADR/IATA/IMDG transport, the cost of shipping will be higher.

When it comes to pure nicotine ADR transport, we can usually send up to 4L packed within one UN certified box, so this does not change the shipment value.

Regardless of the customers order 1L or 4L, the price for shipping will be the same on the condition that the place of destination remains unchanged. Of course, that does not mean that we are limited to 4L packaging only, we are able to pack up to 140L into one UN certified box.

All in all, from the economic reasons it is better to order larger quantities, however, the value of each shipment is determined individually for a given order.

3. Nicotine Product: Storing

Proper storage prevents the products from losing their properties and serves to keep their standard value as long as possible, for the safety of the end customer. Storing raw materials for e-liquid production depends on their level of nicotine.

Low concentration nicotine products (below 36mg/ml) and non-nicotine products should be stored in a cool, dry and dark place.

When it comes to high-concentration nicotine bases and nicotine salts, they should be stored in a similar way to pure nicotine, which is a more complex process that demands a separate description.

Learn more:

- Storing And Handling Pure Nicotine And Nicotine Salts

- 4 Nic Salt’s Features You May Benefit From

- What Is Nicotine And How Is It Classified?

- From Leaves To Labs: A Brief Story About Nicotine’s Production

- Hard To Handle, Easy To Vape: How To Work With Nicotine Safely?

- Nicotine Absorption And Nicotine Salts

- NicSalt Shots vs. NicShots: Final Comparison

- POD Systems vs. Nicotine Salts And Their Growing Popularity

Let’s sum up the most important facts about nicotine!

Do not hesitate to contact us!

At Chemnovatic we care about the highest product standards and the quality of packaging as well as the conditions of transport, so that the products purchased by our customers reach them as soon as possible, safely, and intact.

If you want to ask about the estimated cost of shipping goods, or you have any questions regarding packaging, transport, storage or products’ handling, please comment on this article or contact our sales department specialists at sales@chemnovatic.com.

Let’s grow your business together!

Subscribe to our newsletter and receive a free access to our e-mail course on raw materials for e-liquids production (and more!).

No spam, only valuable content we promise to send you.

Hello dear, well informative blog. I will prefer to refer your content to my friends.

Hi! Thank you, we are very happy you find our blog useful and share info with others. It means a lot to us :) Stay tuned for more articles as we will bring even more vape industry knowledge :)